Clean Room Classification Iso Vs Eu

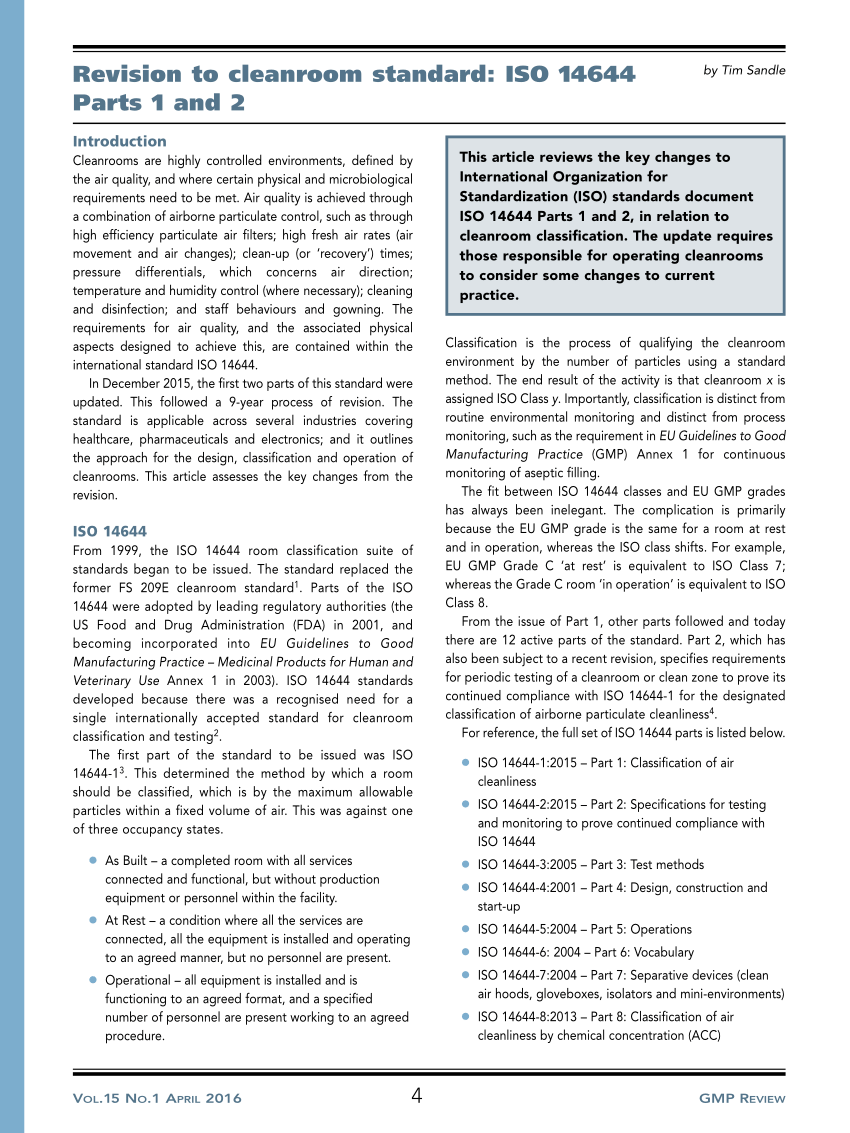

For cleanrooms and clean zones shown in iso 14644 1 2015 cleanroom limits for airborne particulate contamination clean room and clean air device classification in relation to gmp 2008.

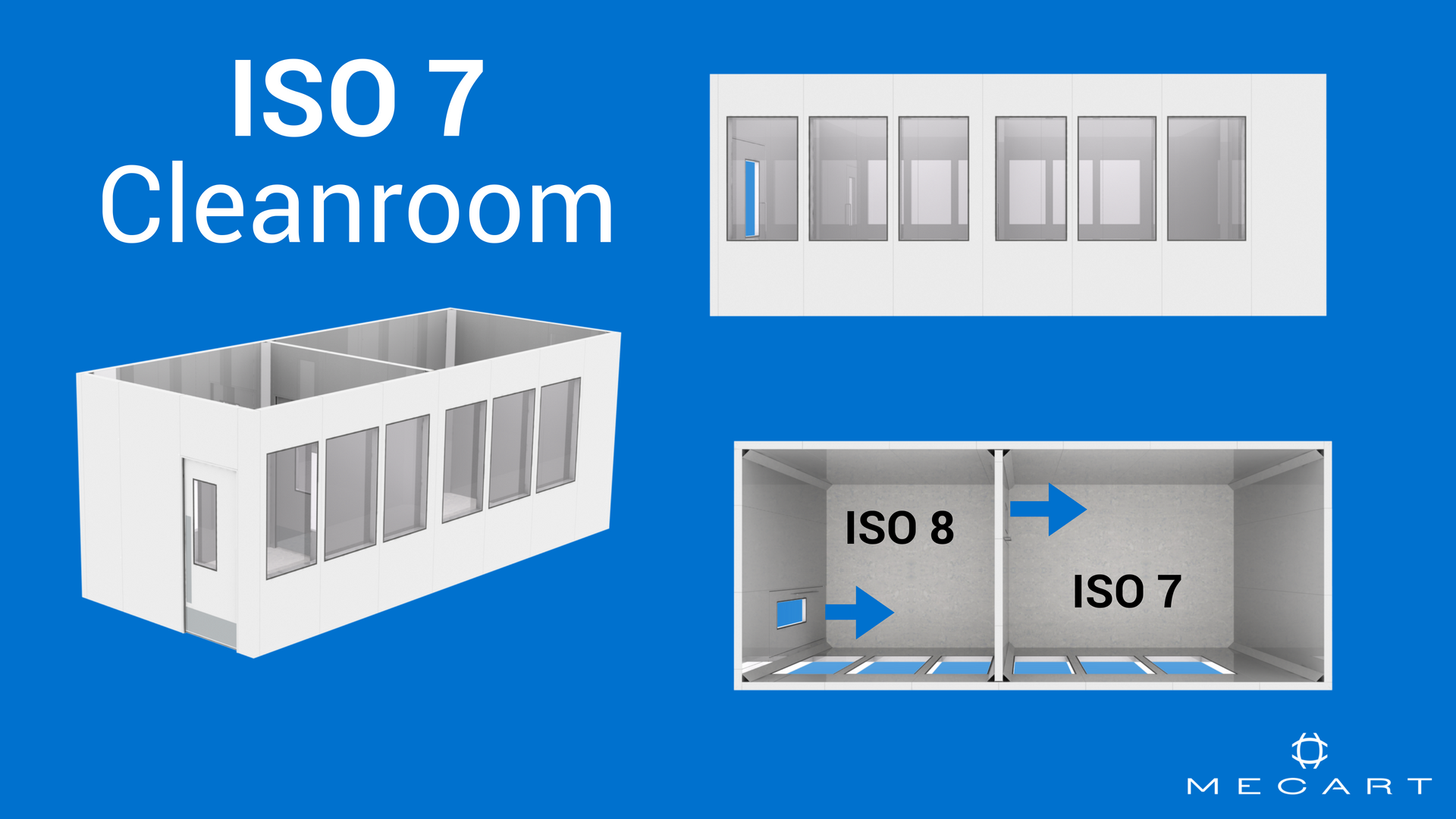

Clean room classification iso vs eu. The particles range in size from 1 5 microns µm. Grade c with class 10000 m 5 5 iso 7 and grade d with class 100000 m 6 5 iso 8. Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image. By comparison a typical office space would be 5 10 times more dirty.

B the guidance given for the maximum permitted number of particles in the at rest condition corresponds approximately to the us federal standard 209e and the iso classifications as follows. A cleanroom must have less than 35 200 000 particles 0 5 micron per cubic meter and 20 hepa filtered air changes per hour. Classification 1 is the cleanest. The class defines a minimum cleanliness level not a specific design.

Ordinary room air is around class 1 000 000 or iso 9. However class will greatly impact design considerations such as filtration hvac requirements and other design elements. Iso 14644 1 and iso 14698 are non governmental standards developed by the international organization for standardization iso. Under the fed ste 209e system there was no equivalent for this level of cleanliness.

The equivalent fed standard is class 100 000 or 100 000 particles per cubic foot. Maximum permitted number of particles per m 3 equal to or greater than the tabulated size. The latter to cleanrooms where biocontamination may be an issue. Whereas cleanliness standards were once defined by the federal standard 209e they have been replaced and simplified by iso with classifications 1 to 9.

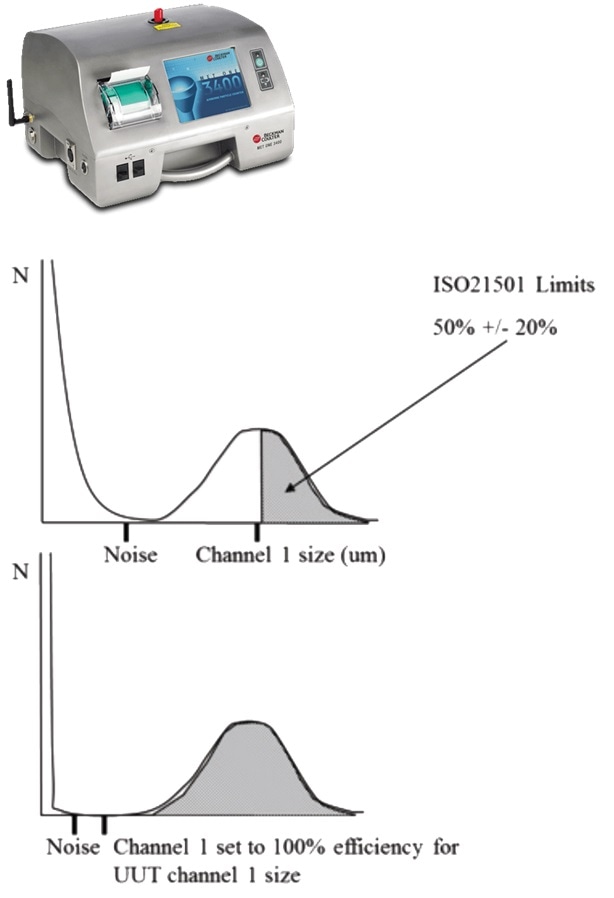

To meet requirements of a clean room as defined by federal standard 209e and newer iso standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class. In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock. Grades a and b correspond with class 100 m 3 5 iso 5. Iso 14644 1 and older standard fs 209e determine class by the concentration levels of particles.

Iso 14644 1 and iso 14698. Clean room classifications can be confusing. If you do business in europe and are installing a clean room that deals with the manufacture of sterile medicinal products your clean room must adhere to the most recent set of standards set forth in the revision of the annex to the eu guide to good manufacturing practice manufacture of sterile medicinal products. Classification 9 is defined as room air.