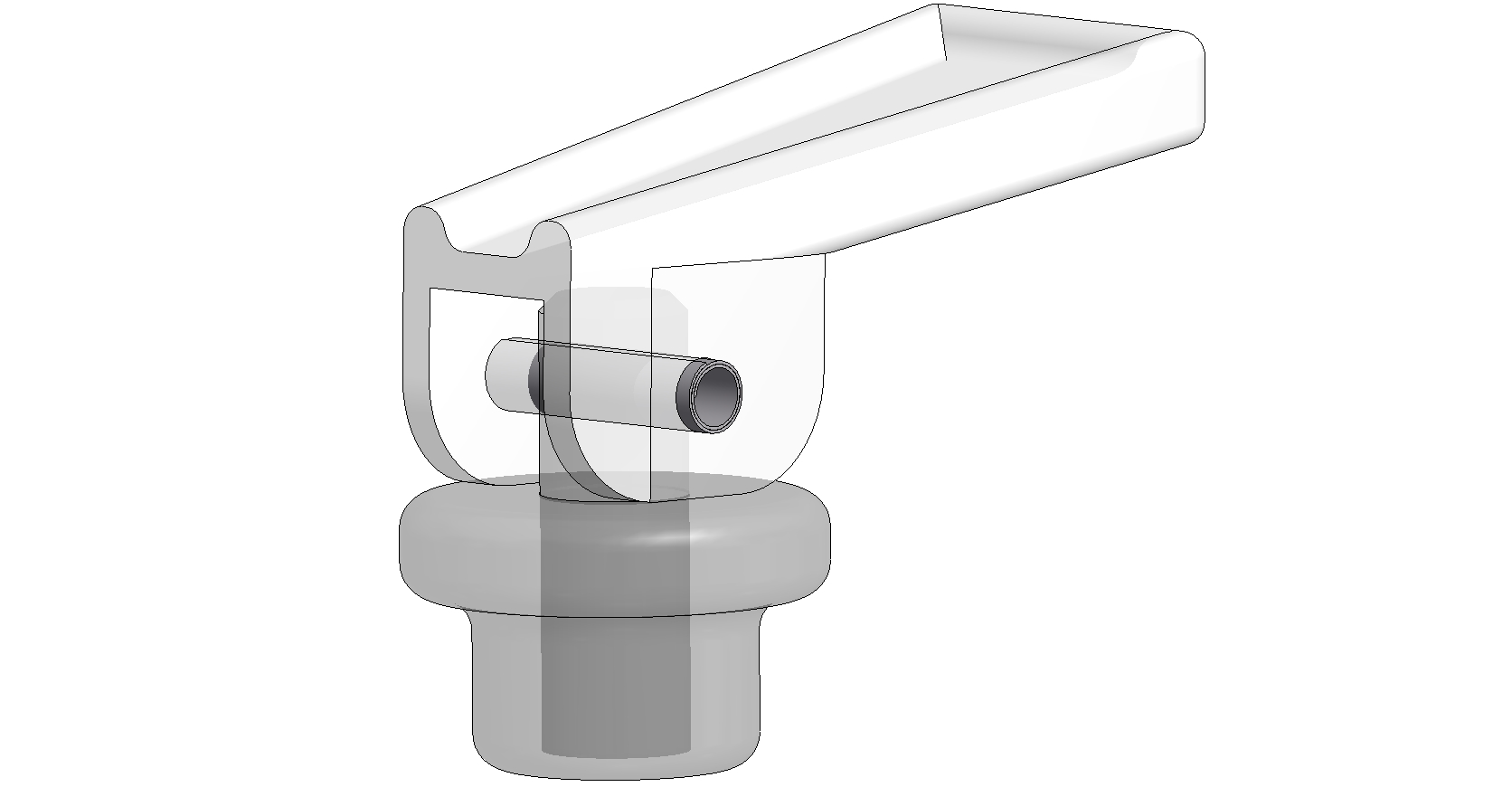

Coiled Spring Pin Removal

Using coiled spring pins as an alternative to bolts rivets dowels slotted spring pins welding adhesives and other joining methods can help your busines.

Coiled spring pin removal. In stock and ready to ship. Coiled spring pins are serviceable fasteners and can be removed with no damage to the host components if done properly. As their name suggests roll pin removal tools are designed specifically for popping broken or stuck roll pins out of their housing in pieces of metal. Choose from our selection of coiled spring pin insert tools in a wide range of styles and sizes.

Remove the spindle steering knuckle assembly. Spring loaded hinge pin remover. However the level of difficulty for pin removal varies significantly by hole type. The magnetic tip holds pins in place.

For pin style. Use the wire or string to support the assembly making sure the brake line has slack in it. Spring pins are also easy to insert and remove. The tool has a curved base that s about 2 inches 5 1 cm long.

Squeeze pins closed and install them in a hole slightly smaller than the pin. Carefully lift the spring out of the car and carefully decompress the spring. They remain flexible after installation to absorb shock and vibration and work well in holes that are out of round. 1 16 5 1 2 spring taper dowel.

I ve messed up the trim around my doors a number of times by using a screwdriver and a hammer to pound out stubborn door hinge pins. Even when using the simple and safe removal tip we are going to share with you it is a good idea to don protective gear when doing this job. For higher load applications where vibration and shocks are a problem use a coiled spring pin. I now use my spring loaded nail set to do the job with perfect results.

Strike the head of the tool with a hammer to install. Use them for fastening pivoting and holding. It takes about three shots and the pin is out. Also called a roll pin the spring pin withstands side loads and rotational friction making it ideal for securing shaft and axle connections.

For tough jobs these spiral pins are 30 stronger than our standard coiled spring pins. In an instant a suddenly free coil spring can send a lower a arm crushing down on the toe of the mechanic who unwittingly pulled the pin out of the control arm. Tie a piece of wire or heavy string to the spindle assembly.