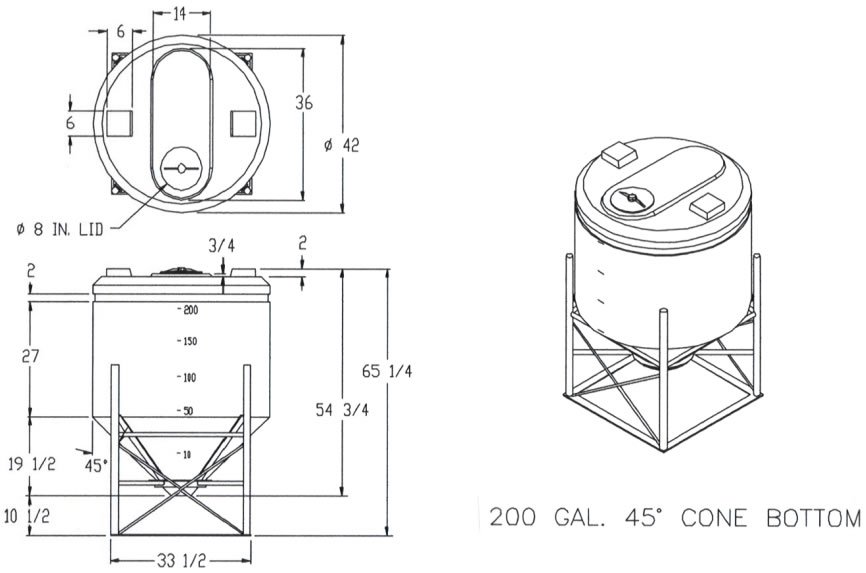

Conical Bottom Tank Design Standard

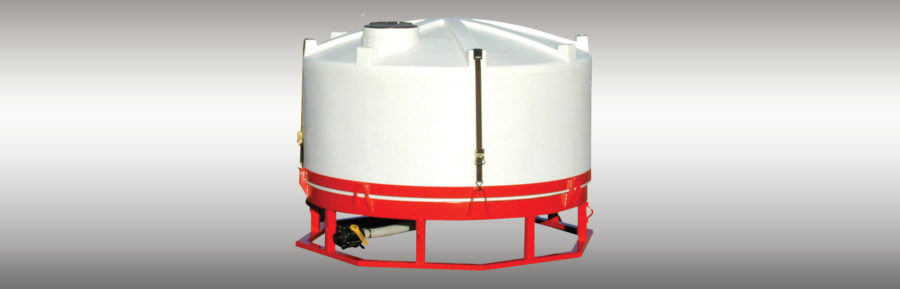

Plastic bulk storage conical bottom tanks with a variety of cone slope angles to ensure safe and complete drainage as well as plastic and steel tank stands.

Conical bottom tank design standard. Cone bottom or conical tanks are ideal for storage applications that require. Tank dimensions may vary depending on manufacturing location please contact factory for drawing. Cone bottom tanks provide the ultimate solution for applications that require complete drainage and are a necessity for efficient processing of some liquids. From standard rectangular and cylindrical tanks to capsule and elliptical tanks.

Standard a s m e tank heads for industry. Plastic cone bottom tanks. There are four basic geometries of mixing tank head design. Baker tank head manufactures semi elliptical tank heads asme flanged and dished tank heads asme 10 10 flanged and dished tank heads asme high crown flanged and dished tank heads flanged and conical dished tank heads standard flanged and dished tank heads flanges and shallow dished tank heads flanged only tank heads dished only tank heads.

Cone bottom tanks range from 2 5 gallons on up to 11 500 gallons. With excellent low temperature impact resistance the tanks are uv stabilized against degradation by sunlight. Cylindrical the head which is the name for the bottom of the tank for whatever reason can have just as much effect. Flat dished sloped and cone.

Food grade cone bottom tanks are available from locations throughout the united states. Resistance to chemicals and corrosive acids solutions. Tanks have 10 bottom clearance. Cone bottom tanks all tanks inductor tanks.

All our stainless steel cone bottom tanks are made using either 304 or 316 stainless steel standard cone slope and diameters are available as well as custom fabrication. With a steep 50 degree cone it ensures the most viscous liquids not able to build up inside the tank. Features of conical tanks. Dimensions listed below and on drawings may vary 3 standard molding tolerance.

All seams are fabricated using a double weldedn process inside outside. Just as the geometry of a tank s sides can affect mixing square vs. Cone bottom tanks include. Cone bottom tank volume conical tank and cone top tanks with this tank volume calculator you can easily estimate what the volume of your container is.