Diesel Engine Connecting Rod Bearing Failure

The oil film is generated by shaft rotation figure b.

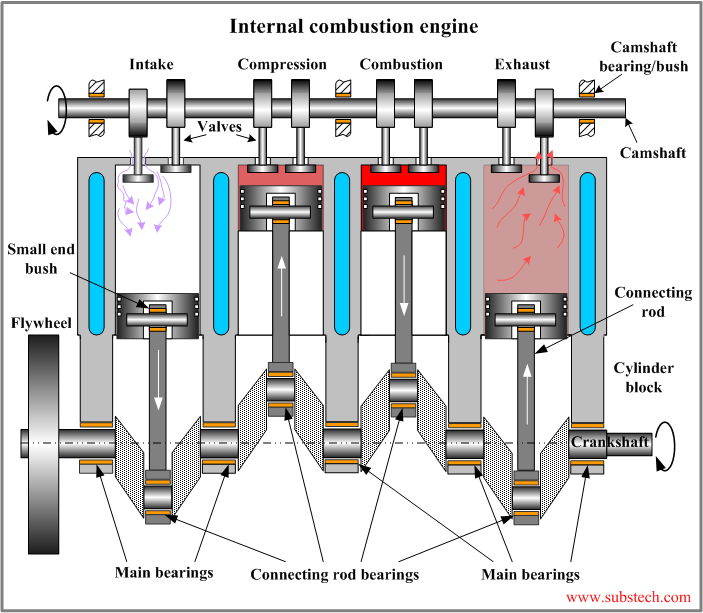

Diesel engine connecting rod bearing failure. Excessive idling can result in an oil film that can not support the load needed. Careful installation procedures are of course critical in every aspect of engine building careless errors are always expensive. Sometimes a fairly new engine can have fatigued connecting rods if it is a rebuilt engine and the mechanic used cheap parts or the wrong parts for the engine. The small end attaches to the gudgeon pin also called piston pin or wrist pin which can swivel in the piston.

Other causes of engine bearing failure. However some smaller engines may instead use a rolling element bearing in order to. At rest the shaft and bearing are in contact. Incorrect clearances will result in seizure of the connecting rod bearing.

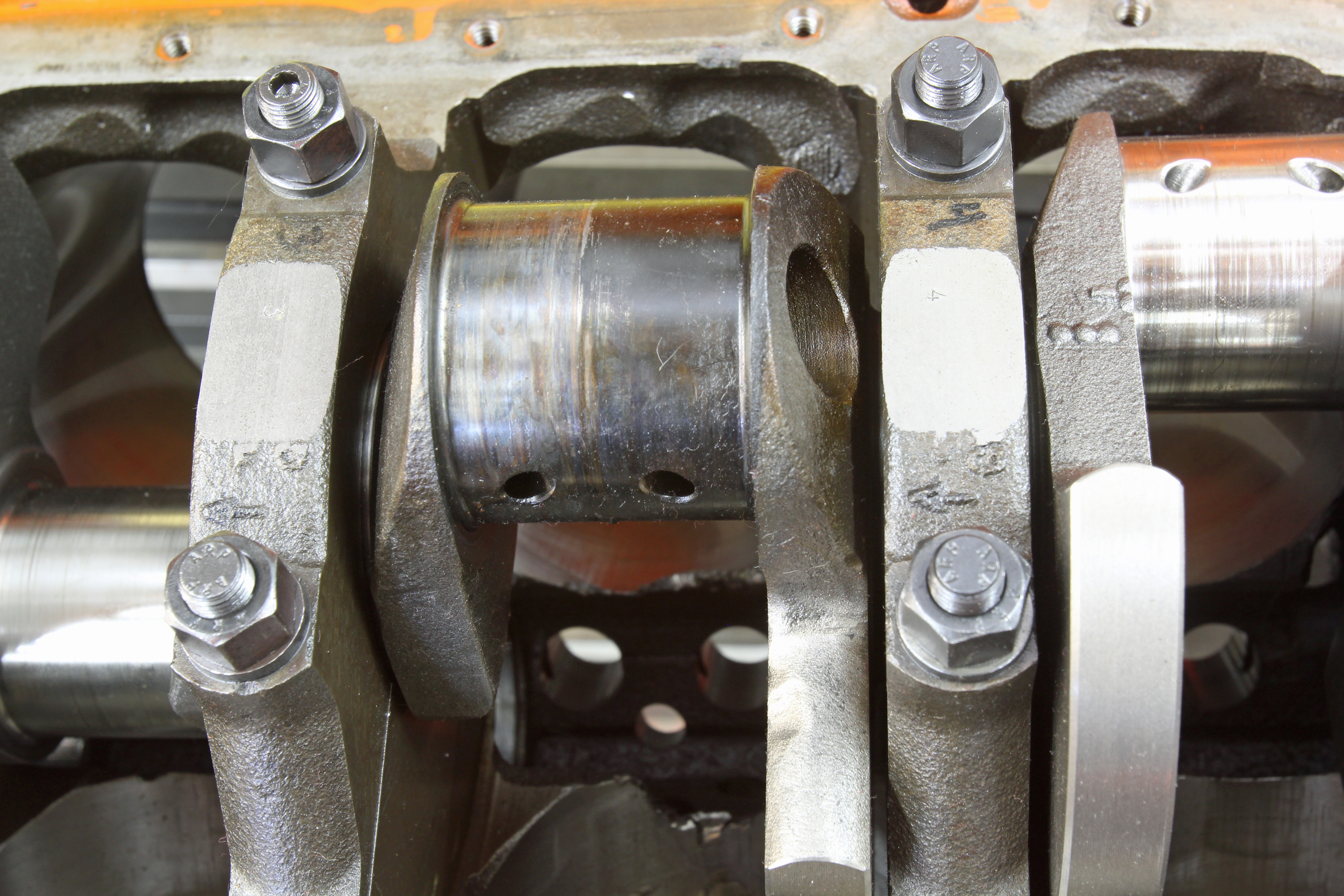

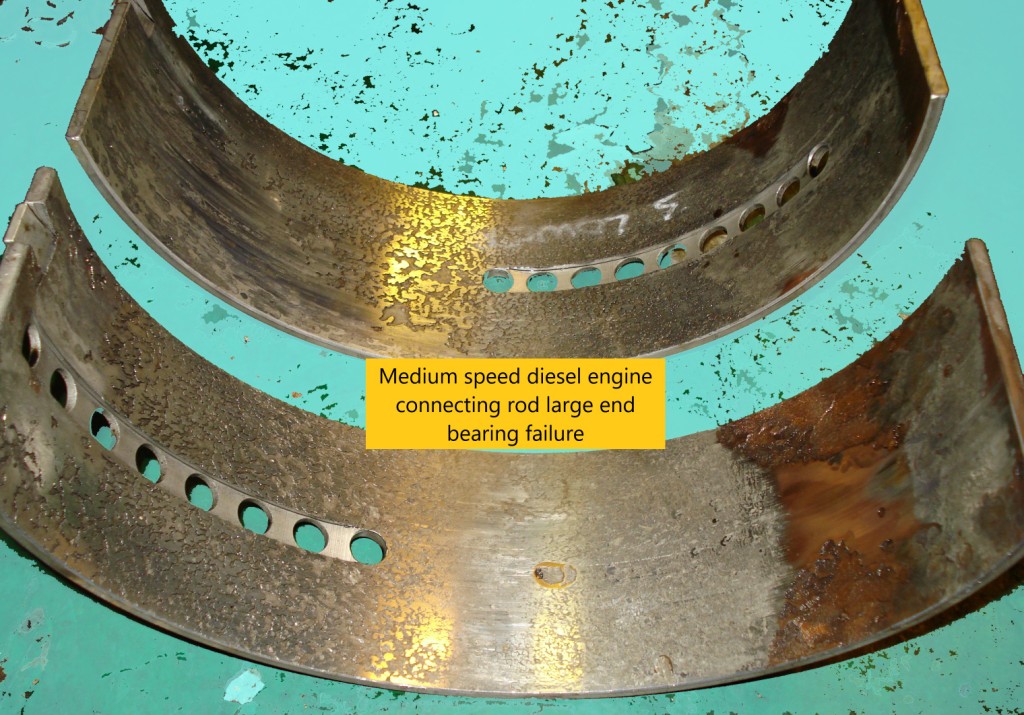

A connecting rod for an internal combustion engine consists of the big end rod and small end. Typically the big end connects to the crankpin using a plain bearing to reduce friction. When a connecting rod or main bearing cap is installed in the wrong position. Bearings fail when the oil film breaks down or when the bearing is overloaded.

The piston cooler if bent can cause a piston to seize and cause the piston pin bearing to fail. If a connecting rod or main bearing cap is installed in the wrong position or a bearing isn t set into place securely lubrication will be insufficient and cause failure. Engine bearings will not function properly if they are installed incorrectly. The following are typical assembly errors most often made in the installation of engine bearings.

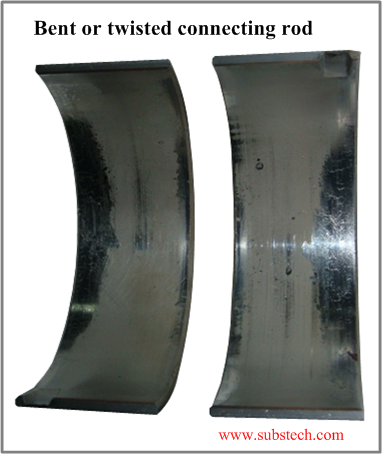

Failures in con rods have been reported in the literature being associated to fatigue overload bending bearing failure improperly adjusted bolts spalling and assembly deficiencies. 2 4 correct reversed position of offset connecting rod reversed bearing caps in wrong or. If a bearing isn t set into place securely lubrication will be insufficient and cause failure. Of all the things that can take your engine out bearing failure is one of the most insidious.

Engine bearing failure analysis. Engine bearings depend on a film of oil to keep shaft and bearing surfaces separated figure a. This paper presents the results of a failure analysis investigation conducted in a connecting rod from a diesel engine 18 v four stroke used in. Catastrophic connecting rod failure can be as a result of incorrect clearances causing bearing failure incorrect torque applied to the fasteners engine over speeding resulting in hyper articulation of the connecting rods and connecting rod bolt failure.

Car oriented types tend to try to ignore bearing issues compensating for them by using ever thicker oil and an eye on the gauges instead of just replacing them as necessary. But bearing wear can have broad ranging. Pin failure the pin that connects the connecting rod to the piston called the piston pin wrist pin or gudgeon pin gets a lot of wear.