Direct Metal Laser Sintering Wiki

Other urethane casting finishing services design services digital rfq marketplace.

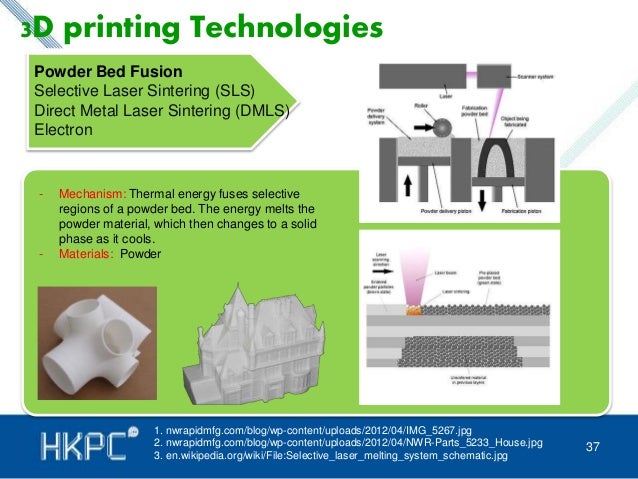

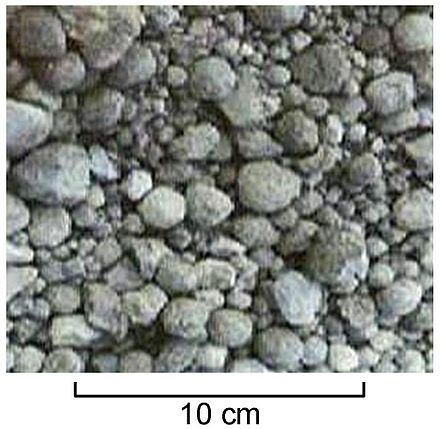

Direct metal laser sintering wiki. Selective laser sintering sls is an additive manufacturing am technique that uses a laser as the power source to sinter powdered material typically nylon or polyamide aiming the laser automatically at points in space defined by a 3d model binding the material together to create a solid structure. Direct metal laser sintering dmls is one of the few 3d printing technologies that directly create a metal part from its 3d computer model. Direct metal laser sintering dmls is an industrial 3d printing process that builds fully functional rapid metal prototypes and production parts in 7 days or less. Dmls design guidelines will help you understand capabilities and limitations.

Direct laser metal sintering dlms also referred to as direct laser metal forming dlmf and selective laser melting slm is a method wherein a highly intensive laser beam is directed onto a metal powder bed and fused metal particles according to a computer aided design file shibli et al 2013. Discover the steps involved in 3d printing metal with direct metal laser sintering. Direct metal laser sintering dmls is an additive metal fabrication technology. Direct metal printing dmp also commonly known as direct metal laser sintering dmls is an additive manufacturing technology that builds high quality complex metal parts from 3d cad data.

This process is an advancement of powder metallurgy pm a mature metal molding technology that uses heat and pressure to form powdered metal parts. Another name for selective laser melting is direct metal laser sintering dmls a name deposited by the eos brand however misleading on the real process because the part is being melted during the production not sintered which means the part is fully dense. In the machine a high precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers one after the other.