Disadvantages Of Foaming In Industrial Fermentation

1 fermentation development and operations merck research laboratories p o.

Disadvantages of foaming in industrial fermentation. This is called foaming and it is caused by high concentration of any solids in the boiler water. It is true that fermented food has some health benefits but there are some disadvantages as well. Key aspects of foaming and its mitigation in fermentation systems are presented. As an example to avoid organic process contamination the fermentation medium air and instrumentation area unit sterilized.

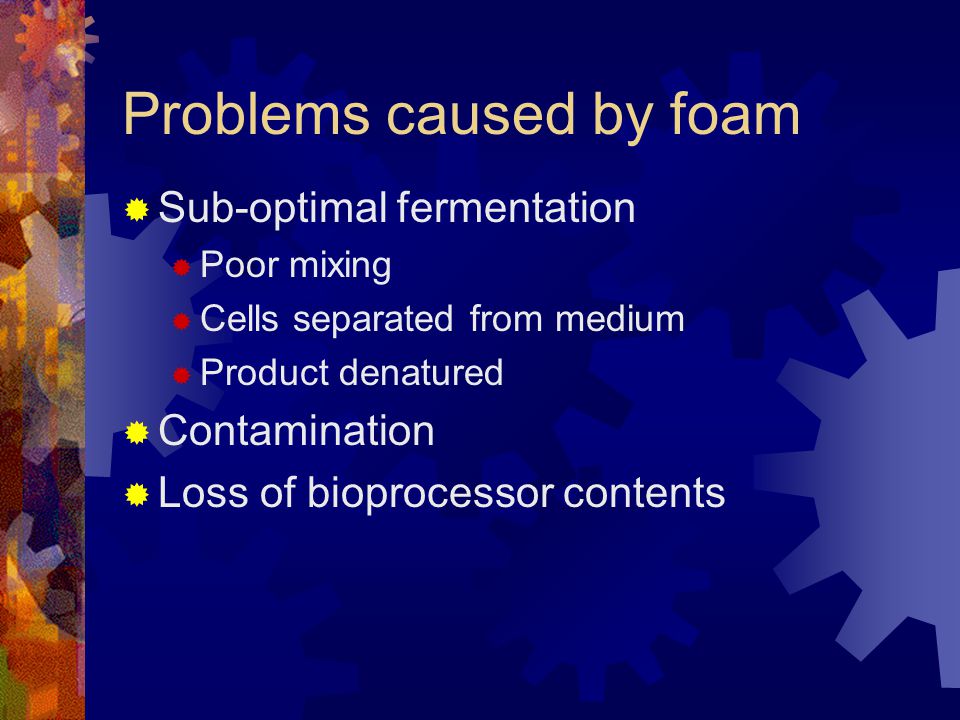

Foam formation is a common phenomenon in many industrial processes including chemical and fermentation processes. Key aspects of foaming and its mitigation in fermentation systems are presented. Some commodity chemicals such as acetic acid citric acid and ethanol are made by fermentation. There are industrial concerns associated with the fermentation method.

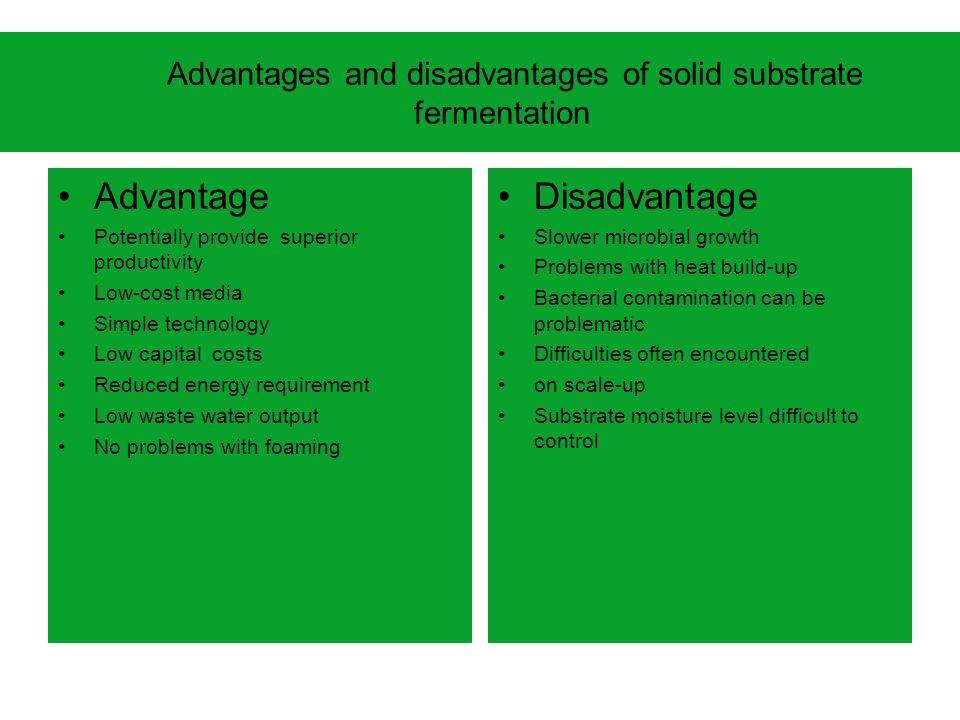

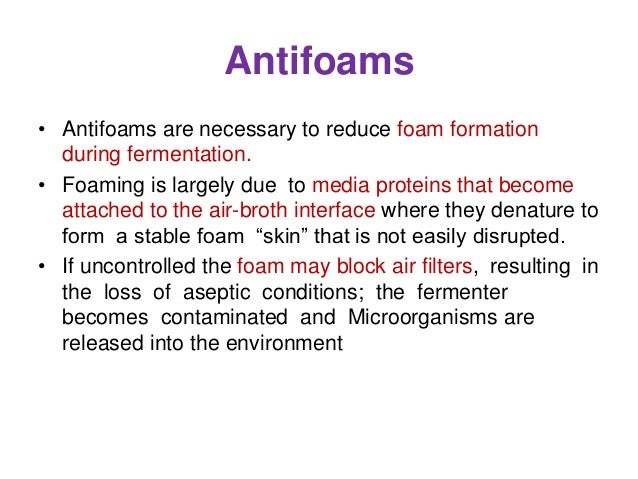

Foam and its mitigation in fermentation systems. A major disadvantage is the cost of media. Foam properties and behavior conditions that affect foaming and consequences of foaming are discussed followed. Industrial fermentation is the intentional use of fermentation by microorganisms such as bacteria and fungi as well as eukaryotic cells like cho cells and insect cells to make products useful to humans fermented products have applications as food as well as in general industry.

Bubbles or froth actually build up on the surface of the boiler water and pass out with the steam. It is generally believed however that specific substances such as alkalis oils fats greases certain types of. Its formation is a desirable property in some processes such as in the production. Boiler water carry over is the contamination of the steam with boiler water solids.

Although there is a big list of advantages of synthetic media there are some disadvantages. Fermentation is a process of preserving food and has been practiced by many cultures for many many years. Synthetic media is never used on industrial scale because it is expensive. Foam management will be achieved by either mechanical foam destruction or chemical anti foaming agents.

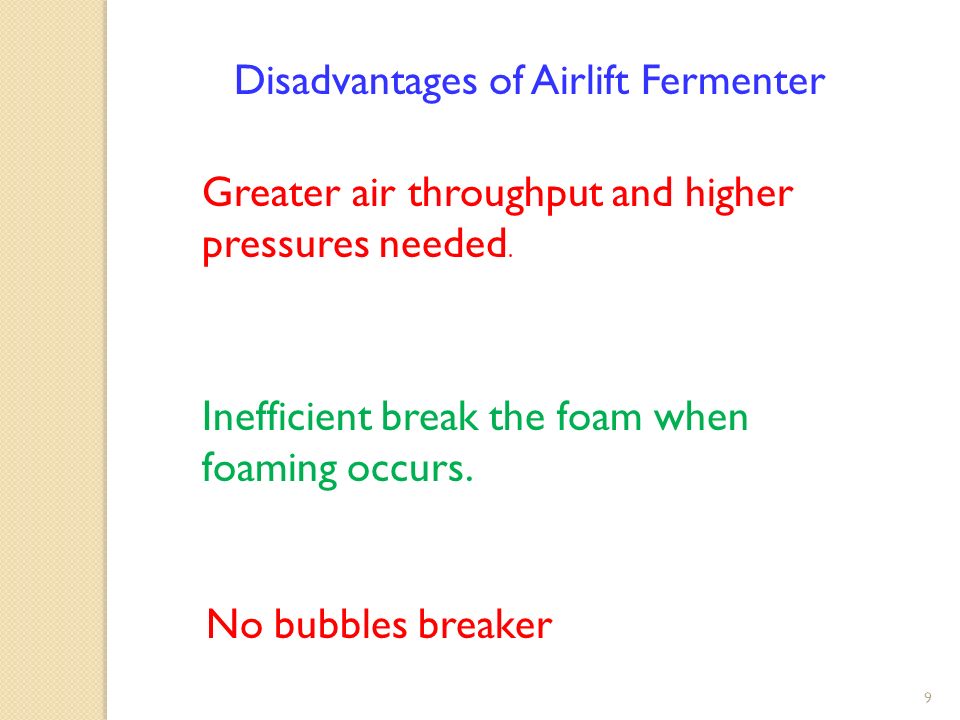

The disadvantages of mechanical foam breakers include high operating costs complicated designs possible shear damage to the product or microorganisms 64 risk of disturbances to the unit operations and their limited effectiveness light foam limited foaming. The most important aspect of fermentation is that it should be economic and profitable. Foam properties and behavior conditions that affect foaming and consequences of foaming are discussed followed by methods to detect and prevent foam both without and with the use of antifoam and their implications. Box 2000 rahway new jersey 07065 usa.