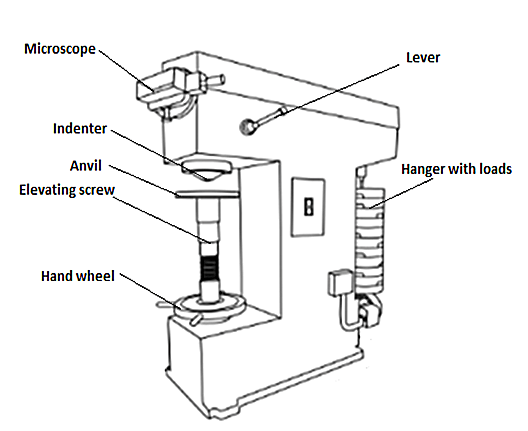

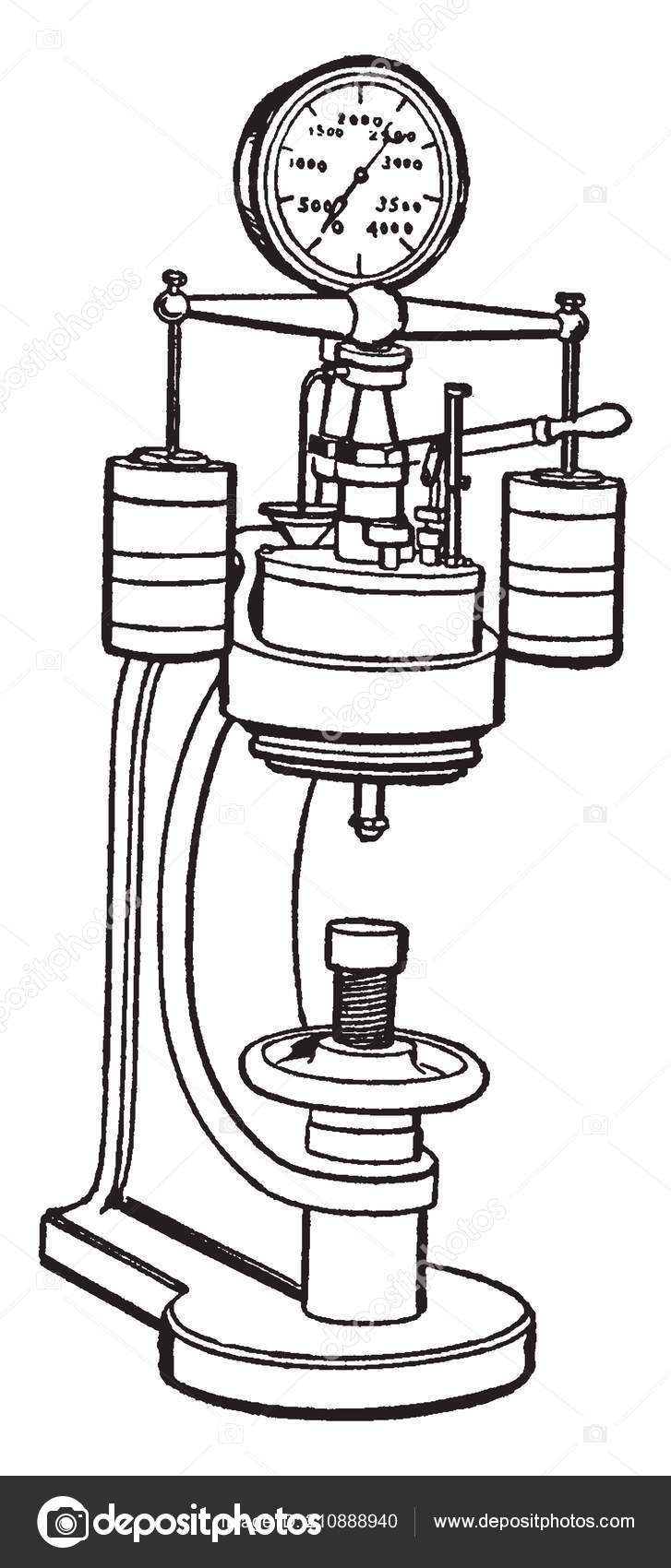

Drawing Brinell Hardness Testing Machine

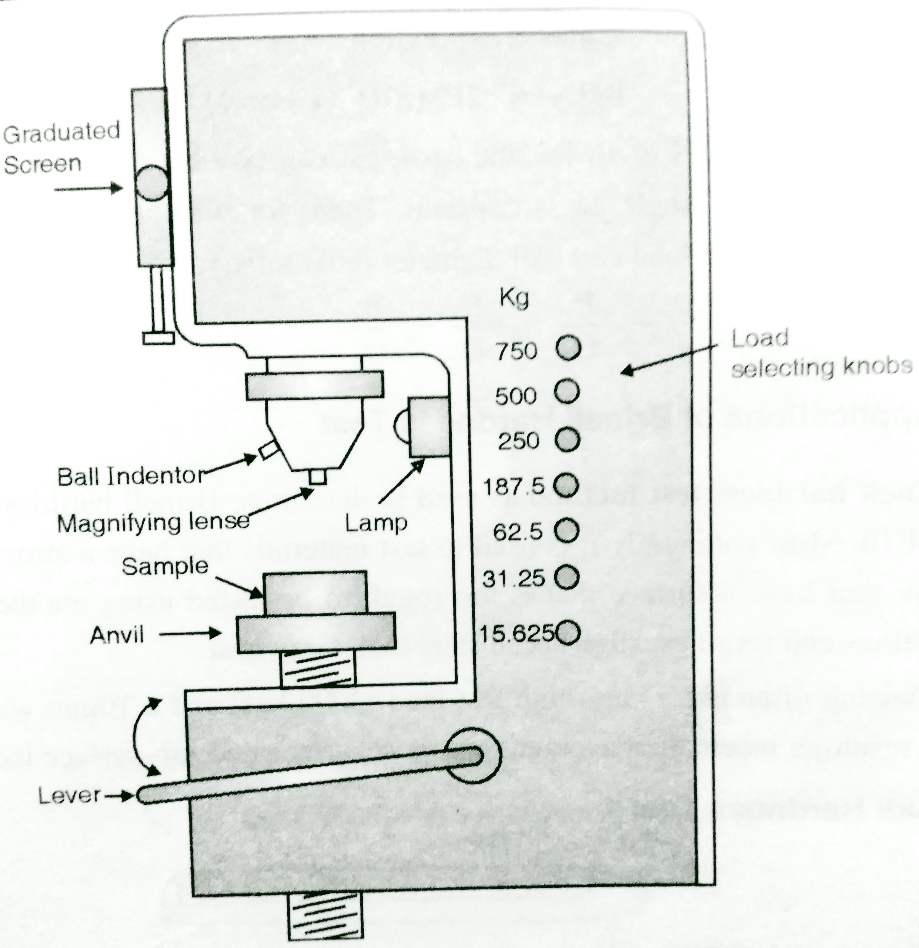

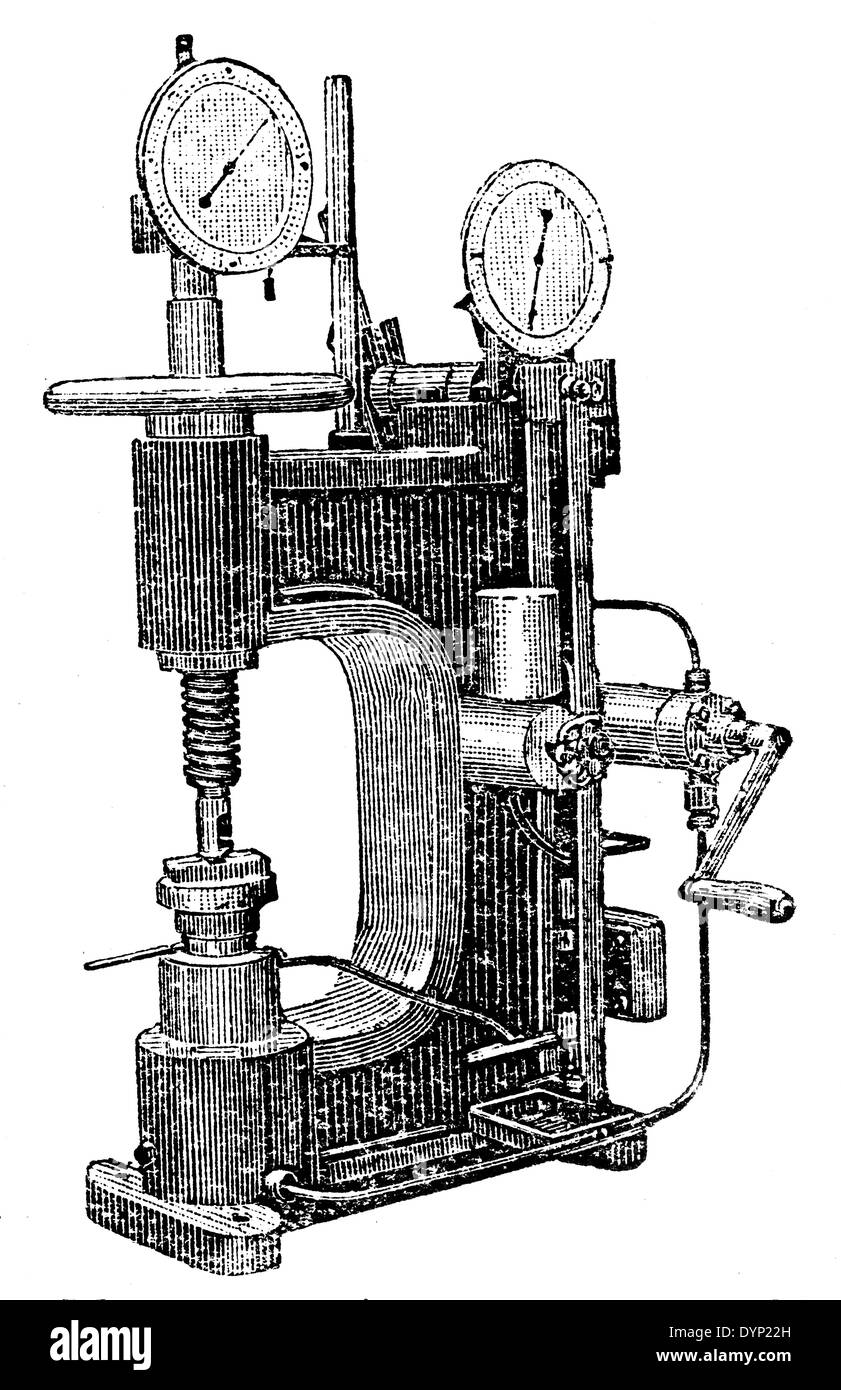

Vickers cum brinell hardness tester.

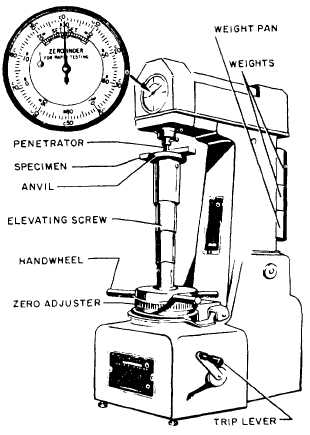

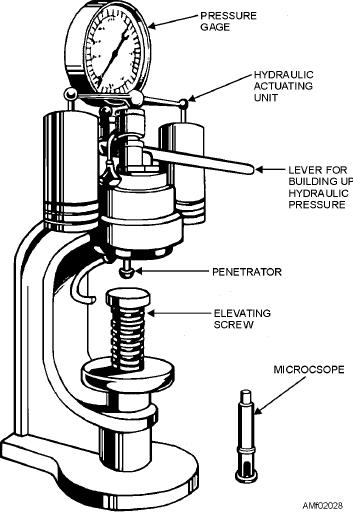

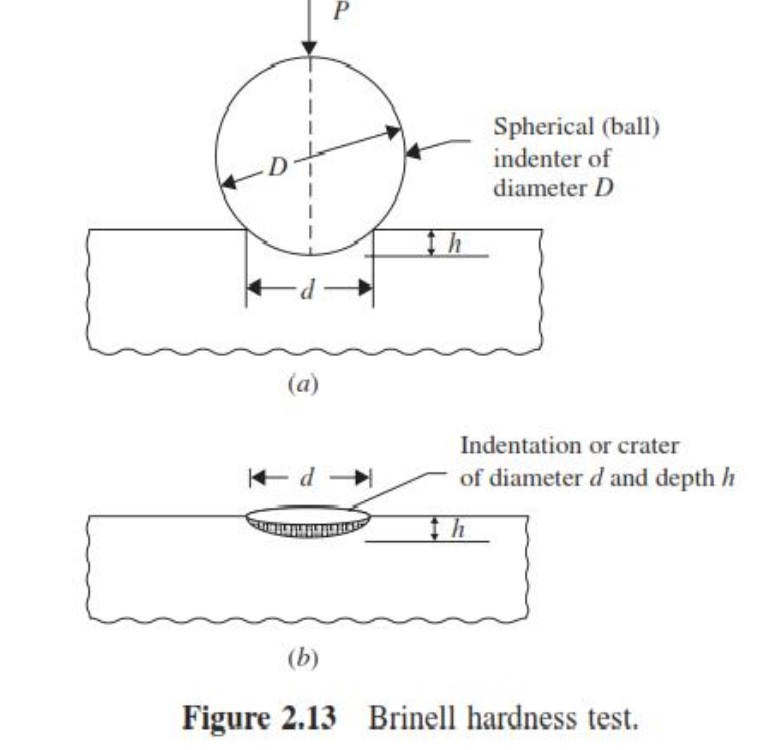

Drawing brinell hardness testing machine. Basic machine design and operation is similar to tkb 3000 with built in an optical device with 14x magnification provided in front to project diameter of ball impression on a glass screen with a micrometer measuring system with 0 01 mm least count. A brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load for a given length of time. Built into the vickers microhardness test machine is a microscope that. The brinell hardness meter uses an impulse force of 9 807n to 29420n depending on the test material and the diameter of the impeller ball.

Ftm has developed brinell hardness testing machine with the optical device. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. Test setup and operation 6 5 1 setting up indenter and anvil 6 5 2 selection of test load 6 5 3 load a test specimen 7 5 4 selecting time at load 7 5 5 initiating a test 7 5 6 test completion 7 5 7 brinell scope measurement 7 6. Test forces range from 500 to 3000 kgf.

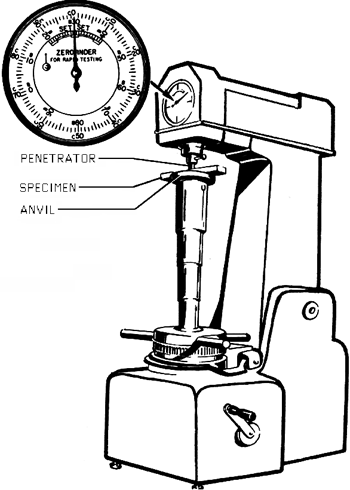

Parts location diagrams 8 7. The brinell hardness test. Unlike with rockwell testing brinell tests measure the diameter of the indentation made by the ball not the depth. Relatively high loads are applied to parts via a tungsten carbide ball in this method.

It 30 it 30 d it 30 astm auto impact 30 auto impact 40 astm. In this machine the indentor swivels and projects diameter of ball. The brinell hardness test hbw indentation leaves a relatively large impression using a tungsten carbide ball. A third option is the vickers hardness test and as with brinell testing calculating the vickers hardness number requires dividing the applied load by the surface area of the indentation.

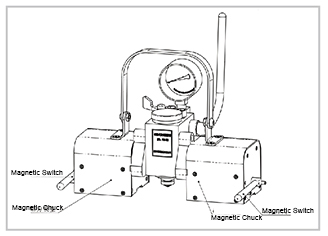

Impact testing machines izod and charpy impact testing machines. Tester footprint drawing for bolting the tester to the work table. Universal load cell based hardness testers. A 10mm ball with an applied load of 3 000 kgf is most common for brinell testing.

The brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The size of the indent is read optically.